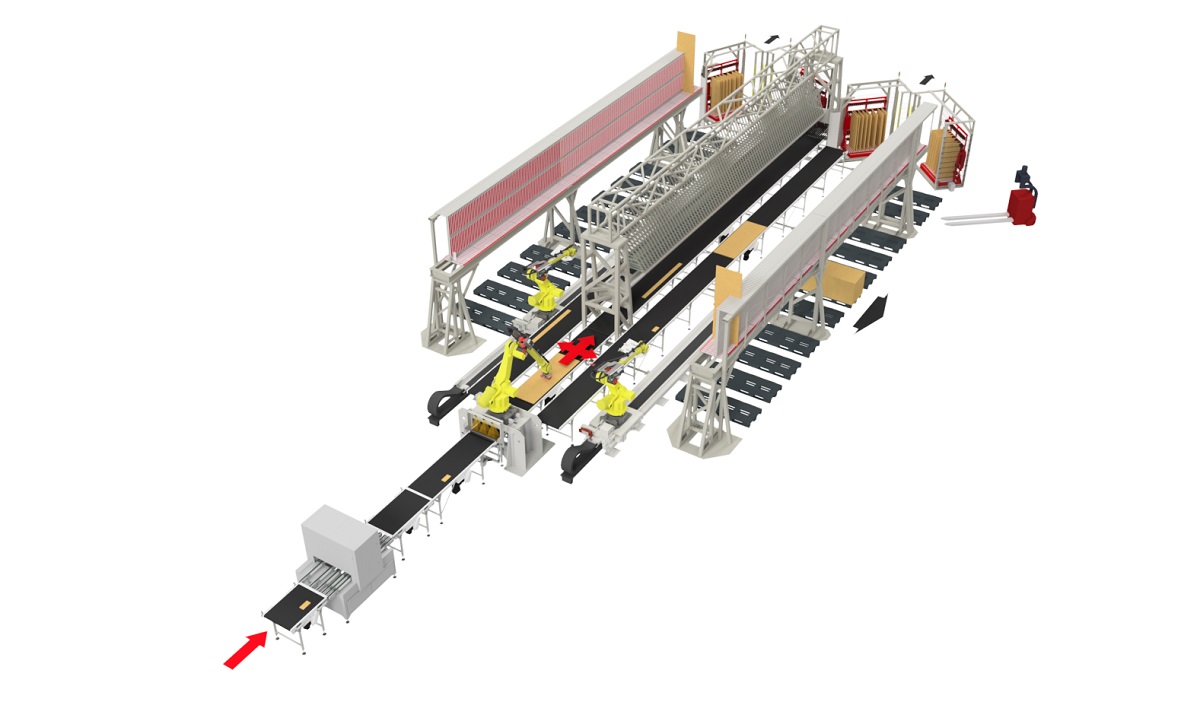

Automated Picking, Sorting, and Stacking

Automated Picking – For Greater Accuracy and Faster Fulfillment

Automation is becoming an essential part of warehouse and logistics operations—and in times of growing labor shortages, it is widely seen as a best practice for sustainable success. The goal is to deliver the right products in the right quantity and sequence for production, shipping, or distribution. With Rotte’s automated picking systems, you achieve new levels of speed, accuracy, and cost-effectiveness.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Our systems use intelligent robotics, precision gripping technologies, and advanced software solutions to guarantee error-free picking—even for small parts, bulky items, or fragile products. Benefits include:

- High picking speeds through fully automated processes

- Reduced error rates thanks to intelligent sensors and data processing

- Optimized storage utilization through dynamic inventory management

- Ergonomic relief for staff and fewer manual tasks

- Improved supply chain management through shorter lead times

- High flexibility through modern robotics and tailored material handling components

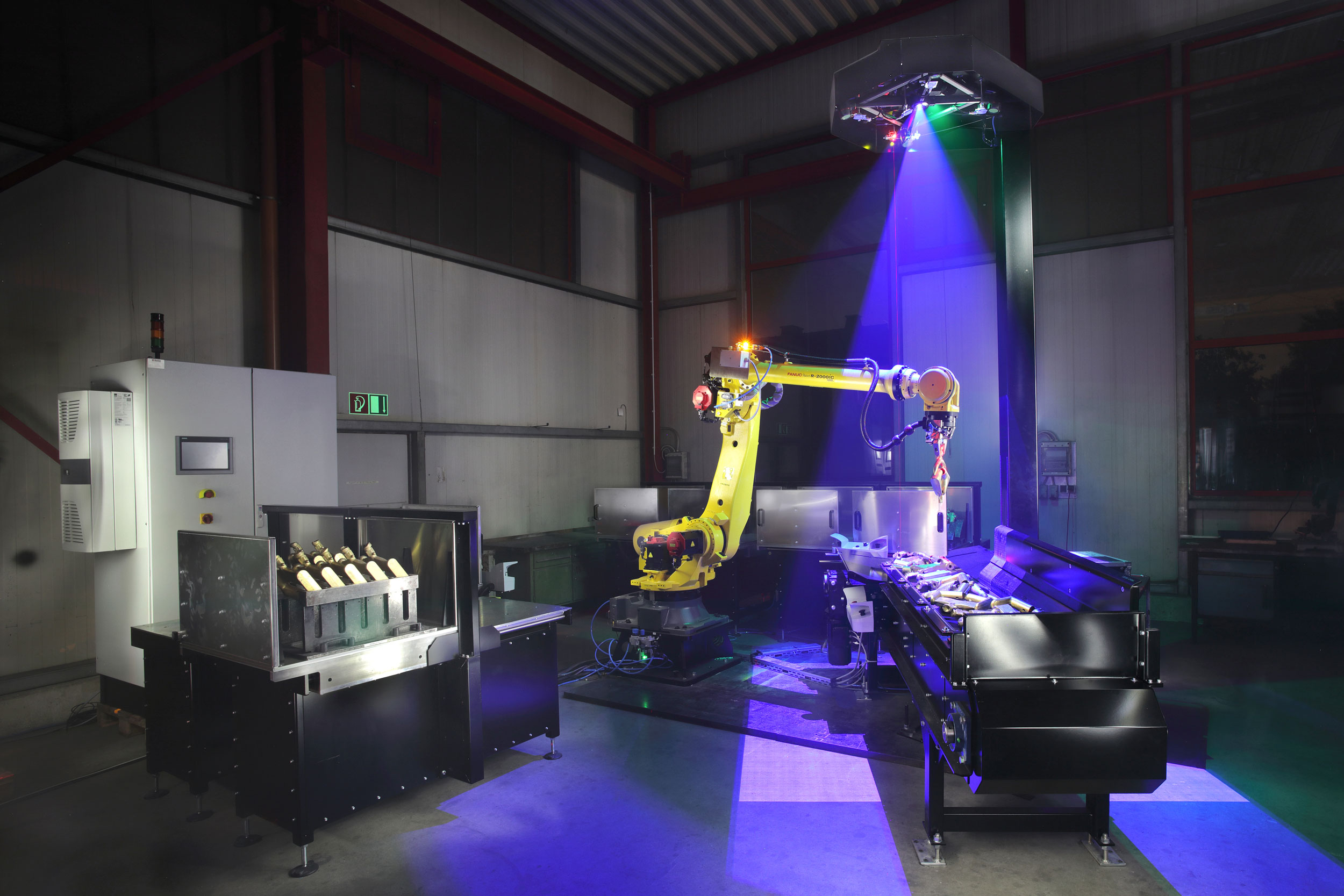

We integrate Pick-by-Light, Pick-by-Vision, or robot-assisted gripping systems into our picking cells to make your operations faster and more efficient. Every picking solution is designed to meet your exact specifications—down to the last detail.

Automated Sorting – Smarter Material Flow Management

Sorting is a critical step in almost every industry—whether in logistics, e-commerce, food processing, or manufacturing. A Rotte automated sorting system delivers maximum efficiency, even with high throughput volumes and complex sorting criteria.

Thanks to advanced vision systems, powerful sensors, and intelligent control software, our sorting systems can process products based on a wide range of characteristics, including:

- Size, weight, and shape

- Color or surface texture

- Barcodes, RFID-Tags oder QR-Codes

- Packaging type or batch information

Our systems are engineered to maintain high-speed, high-accuracy sorting—even with mixed product types. The modular design allows for easy integration into existing material flow systems and flexible expansion as your needs grow.

Automated Stacking – The Foundation of Efficient Logistics

Automated stacking of products, boxes, or pallets is key to optimizing warehouse space and streamlining shipping processes. With Rotte’s automated stacking solutions, you not only speed up operations but also improve workplace safety and eliminate manual errors.

Our robotic stacking systems are precise and reliable, capable of handling a wide range of goods—from small packaging units to heavy pallets. Key advantages include:

- Stable stacks through precise positioning

- Flexible configuration for varying product sizes and weights

- Integrated safety features to prevent damage

- Fast adaptation to changing requirements with simple programming

By using next-generation industrial robots, our stacking solutions provide essential support for your team, add flexibility to your workflows, and improve ergonomic conditions in the workplace.

Rotte Has Your Picking Solution

In nearly every production environment, steps such as sorting, buffering, stacking, and picking are mission-critical. Each step directly impacts the success of subsequent processes. With intelligent technology, these intralogistics tasks can be completed significantly faster and more cost-effectively.

Let’s talk today about how our picking systems can support your company—technically and economically.

Automated Picking with Automated Guided Vehicles (AGVs)

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

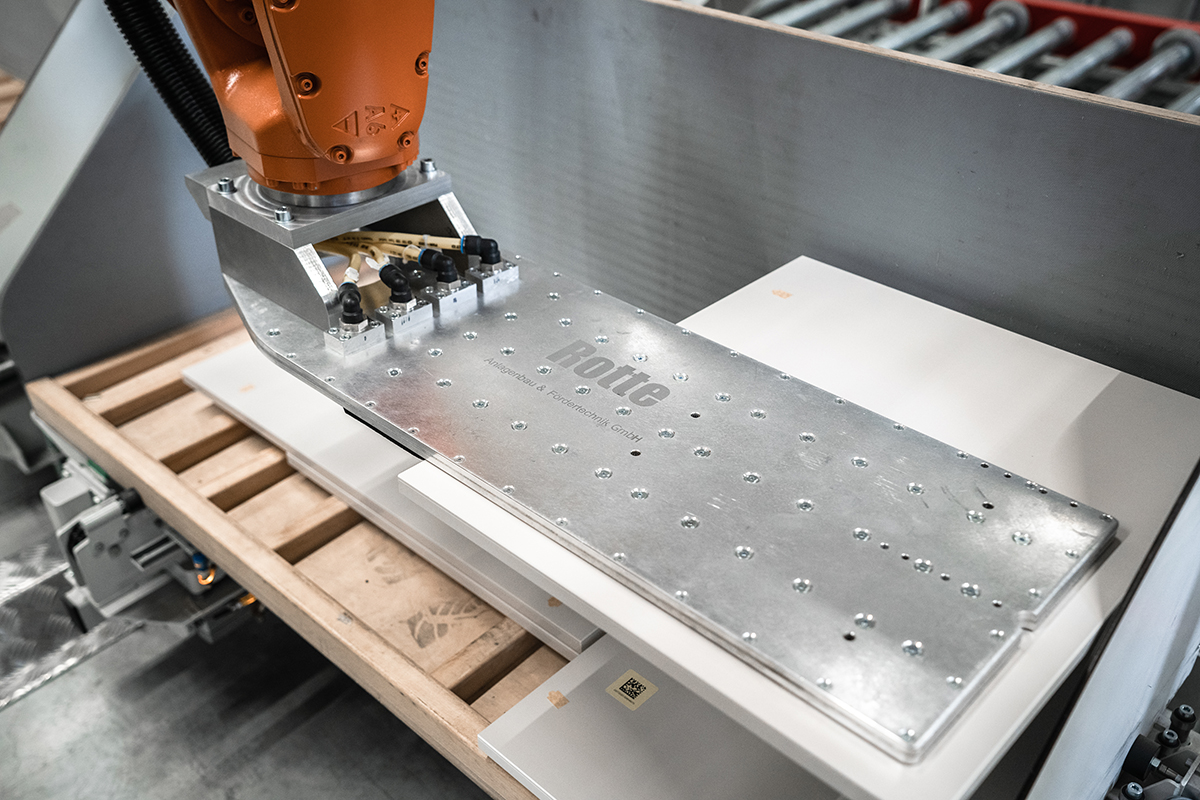

Bin Picking Cell CAMPGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

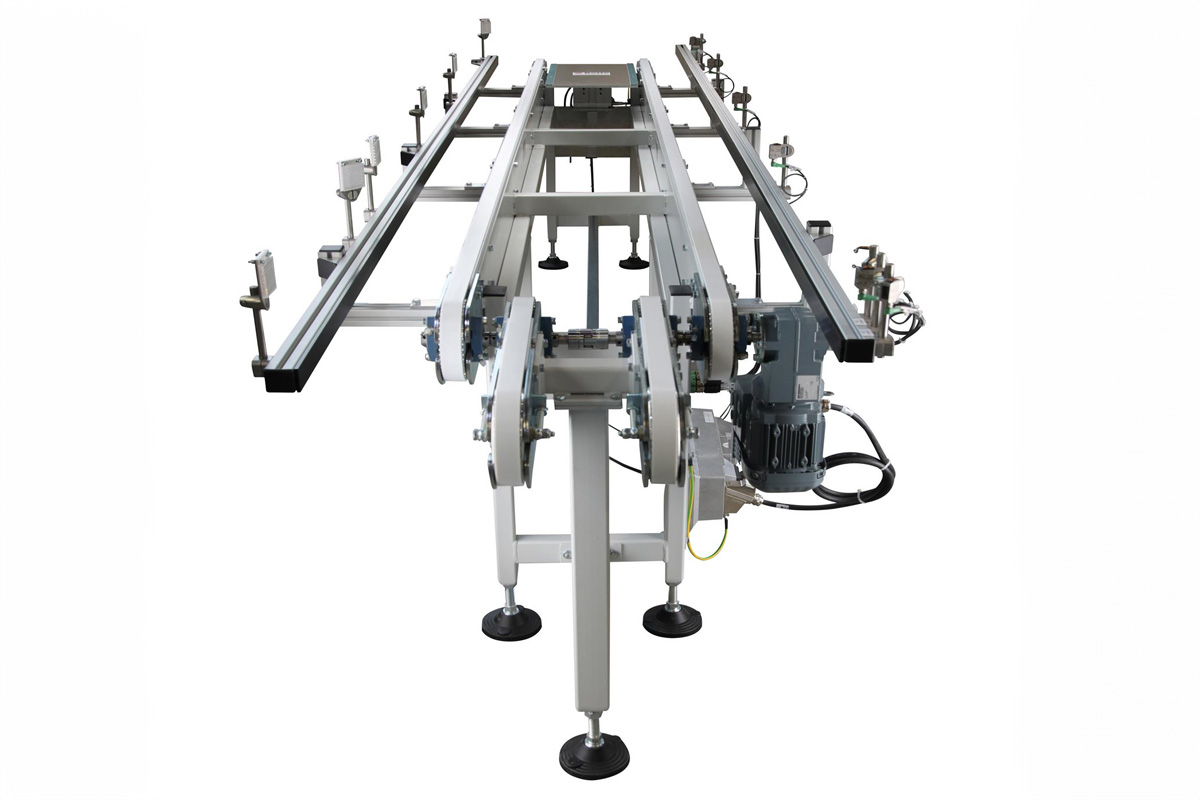

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

For the industrial processing of sealing fleece, filters, and technical fiber materials, Rotte offers high-precision ...

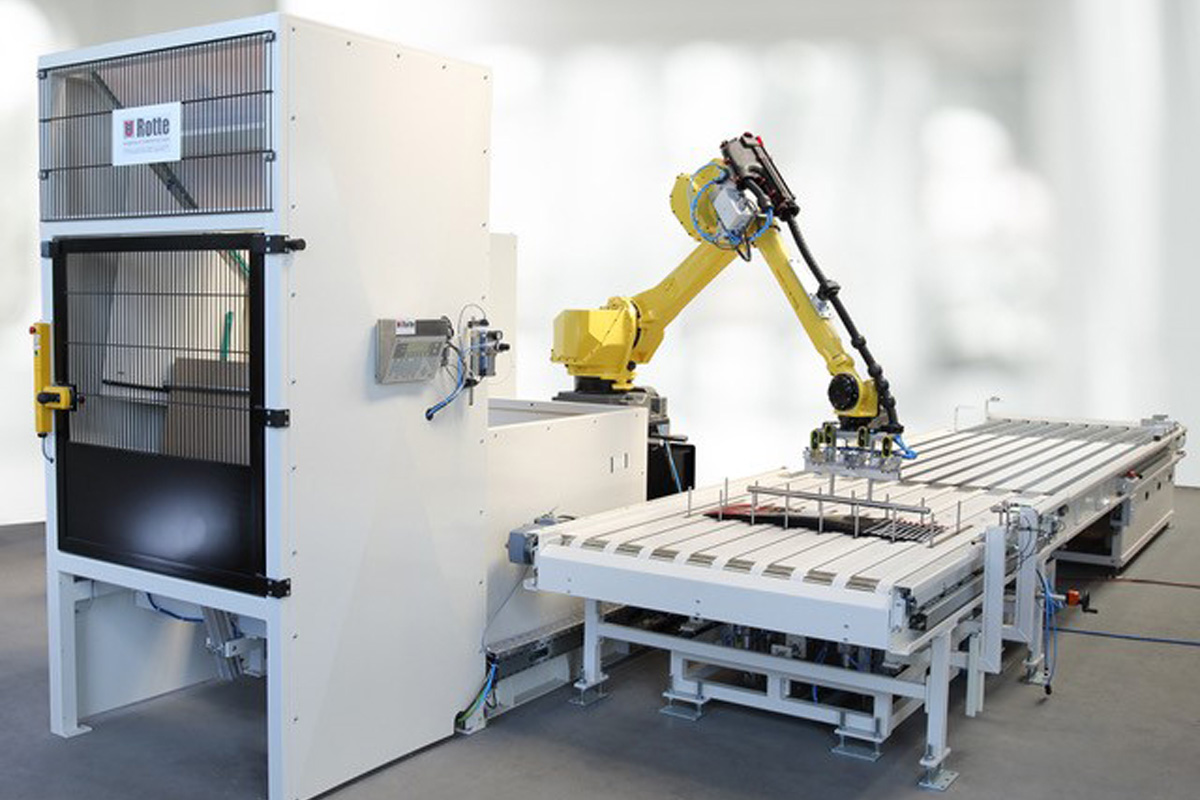

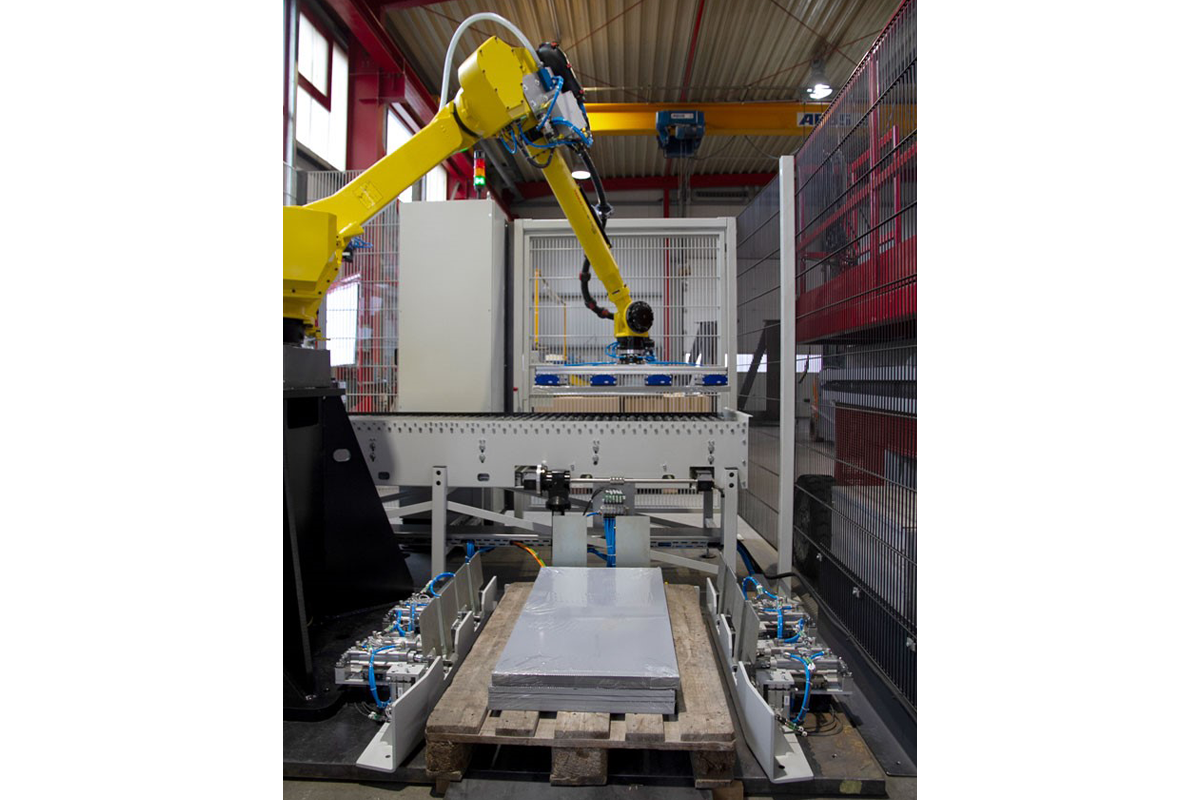

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

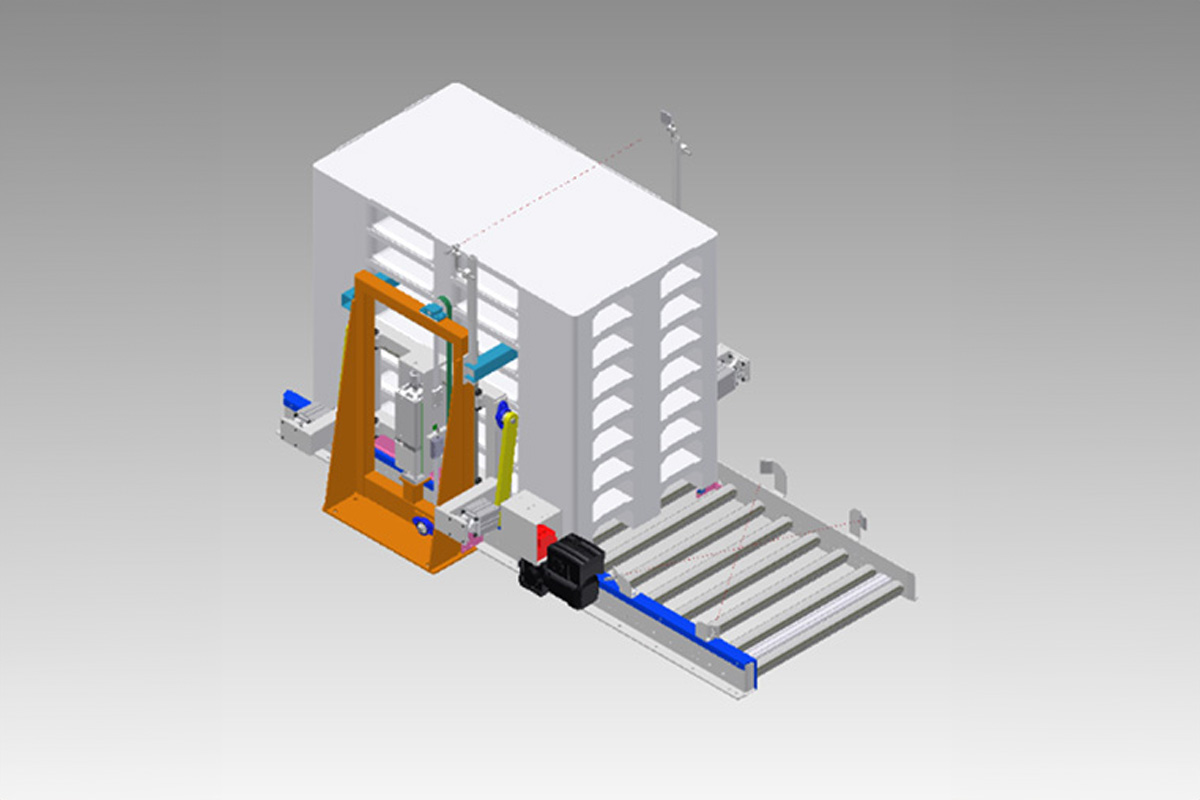

Automated Storage Systems for Multi-Daylight Presses

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...