Automotive Industry

Customized plant and mechanical engineering for the automotive industry - special machines for high performance in series production

The automotive industry has always been characterized by the highest quality requirements, short development cycles and high cost pressure. At the same time, electromobility, digitalization and new mobility concepts are changing production in this industry at an even faster pace. In this highly competitive global environment, Rotte supplies innovative and customized automation solutions for the vehicle and supplier industry. We design and manufacture machines and systems for the production of both passenger cars and commercial vehicles.

Whether it’s vehicle interiors, drivetrain technology, chassis, or bodywork: with our expertise, we develop manufacturing systems that can be precisely adapted to the technical requirements of our clients—reliable, powerful, and process-oriented.

Contact us for production solutions that keep pace with the dynamics of your industry.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Automation Technology as a Complete Solution – More Than Classic Plant and Machinery Construction

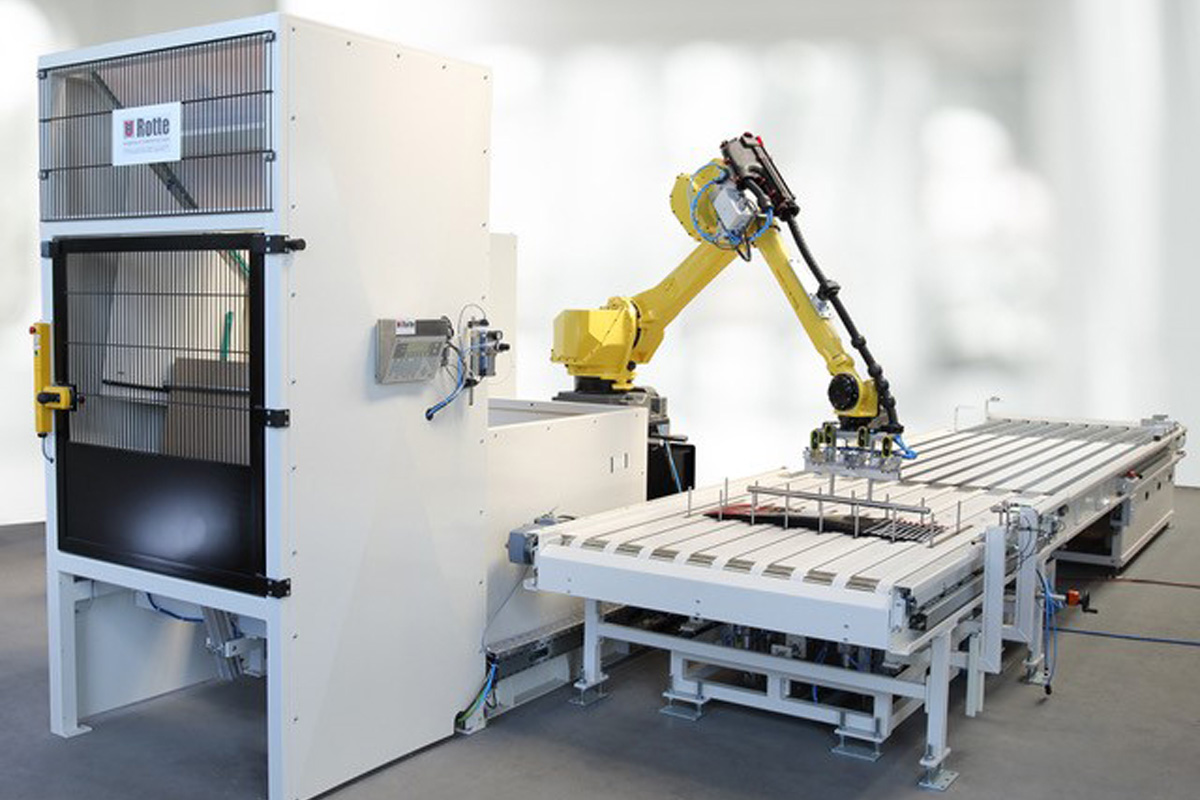

In automotive and commercial vehicle production, every cycle counts. At the same time, processes must be flexible enough to map different vehicle types, model variants and customer-specific options. Rotte develops special machines and complete systems that are tailored precisely to this challenge – modular, networked and ready for Industry 4.0.

Thanks to their modular design, our systems can be quickly adapted to new vehicle models or component variants. Our customers benefit from the fact that, with our team of experts, we can offer them all services from a single source, from development to commissioning and maintenance.

Our systems are used in:

- Assembly processes for cockpit modules, seat systems, dashboards, door panels, and body components

- Handling and feeding of large, heavy, or delicate parts

- Bonding, screwing, and pressing with reliable control and documentation

- Joining processes in chassis, battery, or axle assembly

- Testing and inspection stations for quality assurance and functionality checks

- End-of-line operations including labeling, documentation, and palletizing

Robotics and image processing - key technologies for the automotive industry

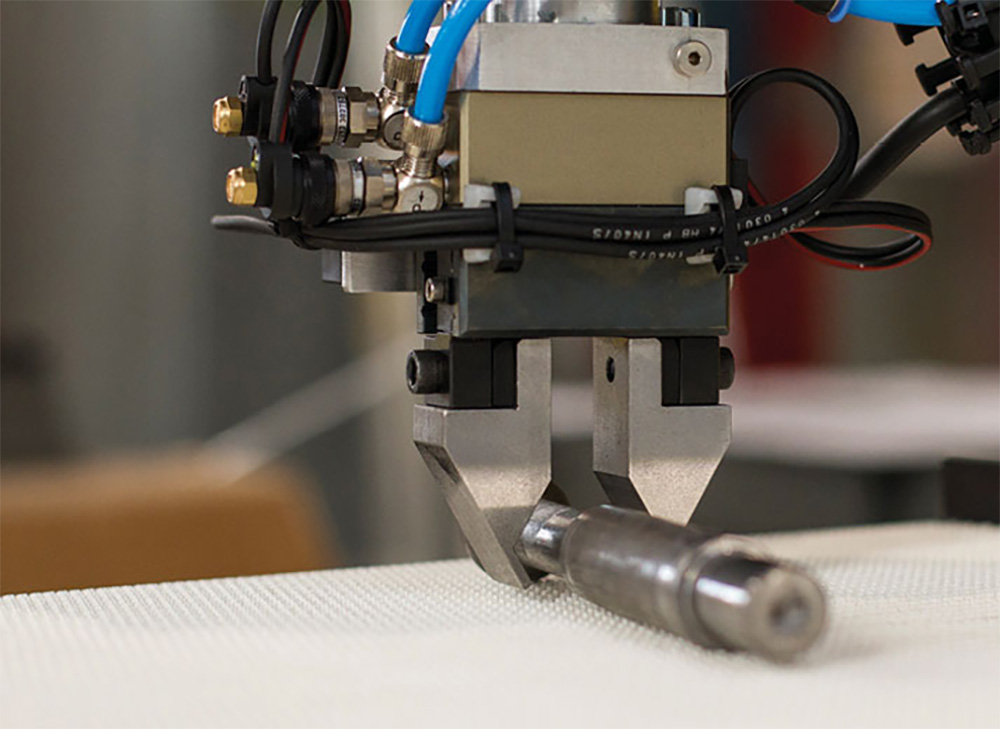

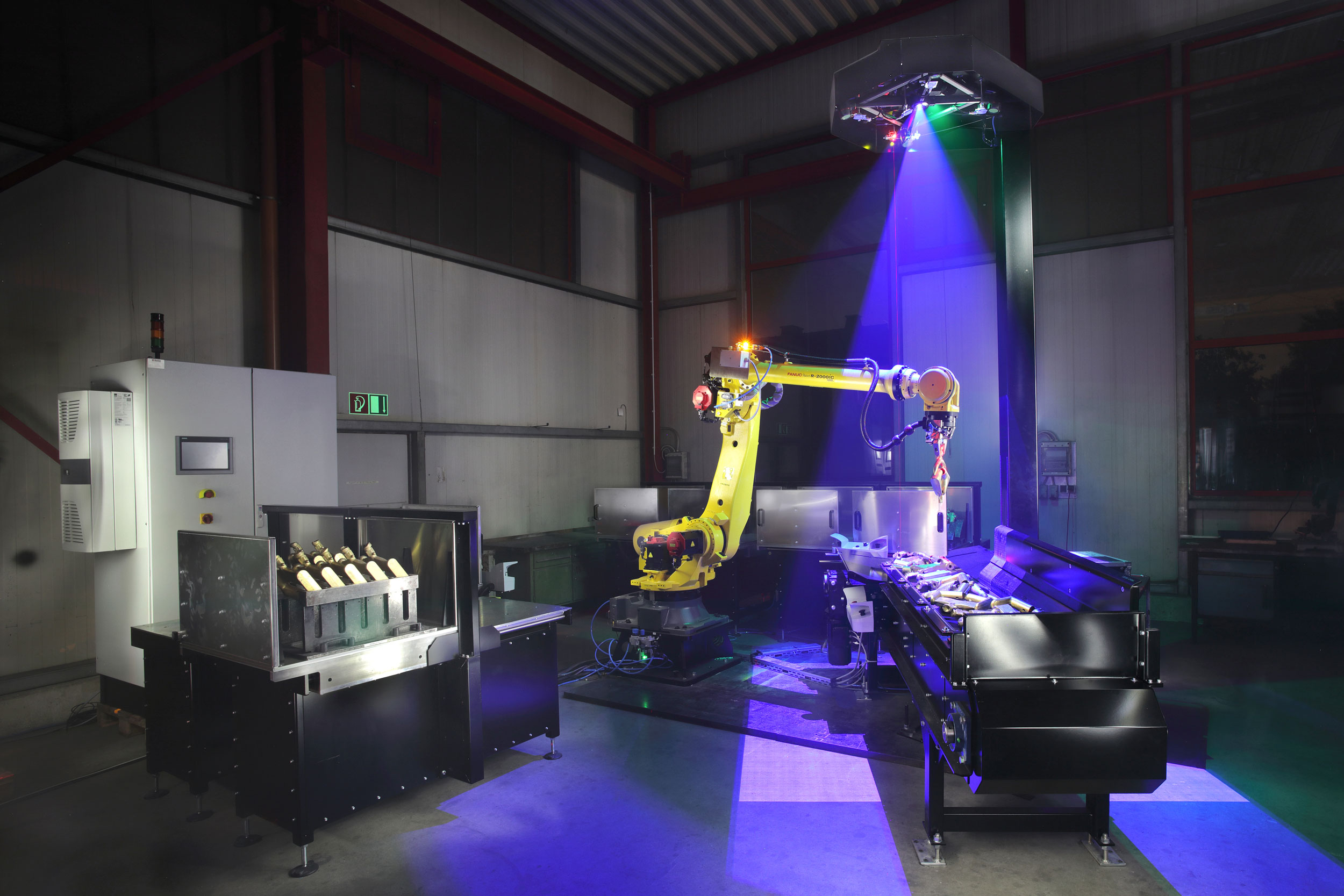

Robotics and Vision Systems – Key Technologies for the Automotive Sector They offer maximum repeat accuracy with minimum cycle times and enable even complex work steps to be automated economically. In combination with intelligent image processing, the result is a system that automatically detects errors, positions components precisely and reliably differentiates between variants.

Intelligent image processing with systems from Rotte enables precise and efficient automation of a wide range of production processes – especially where complex geometries, sensitive components or a high number of variants pose particular challenges. A key area of application here is pick-and-place automation, in which sensitive or heavy components are reliably detected, gripped and positioned. Once implemented, camera-supported component inspection, position detection and dimensional control allow components to be reliably identified and precisely aligned – a basic requirement for subsequent further processing.

Our systems are also used in robot-assisted joining and assembly applications, where they ensure consistently high precision. The automated application of sealants and adhesives is also efficient and reproducible thanks to smart path tracking.

The flexible robot cells from Rotte are particularly suitable for work with variable parameters. The robot systems can be easily adapted to changing products and geometries. This means that the possibility of continuous further development of your products is integrated as a key feature right from the start. Especially for applications in the production of vehicle interiors, battery modules or lightweight components, the combination of robotics and image processing allows for unsurpassed stable, reliable processes and consistently high product quality.

Rotte as General Contractor – Turnkey Solutions for Your Vehicle Production

Are you looking for a partner who takes a holistic approach to your requirements? As a general contractor, we implement turnkey production systems for OEMs, Tier 1 and Tier 2 suppliers. We plan, design and manufacture, we advise, optimize and maintain so that you can meet the high quality requirements and demand of your customers at all times without compromise. Together with your team, we develop a production concept that makes the best out of every car, commercial vehicle or component manufactured in your plant. Increase productivity and customer satisfaction in equal measure with us at your side – holistic thinking in your interests is our core competence!

Whether it’s electromobility, lightweight construction, or digitalization of your production processes—talk to us now.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Bin Picking Cell CAMPGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

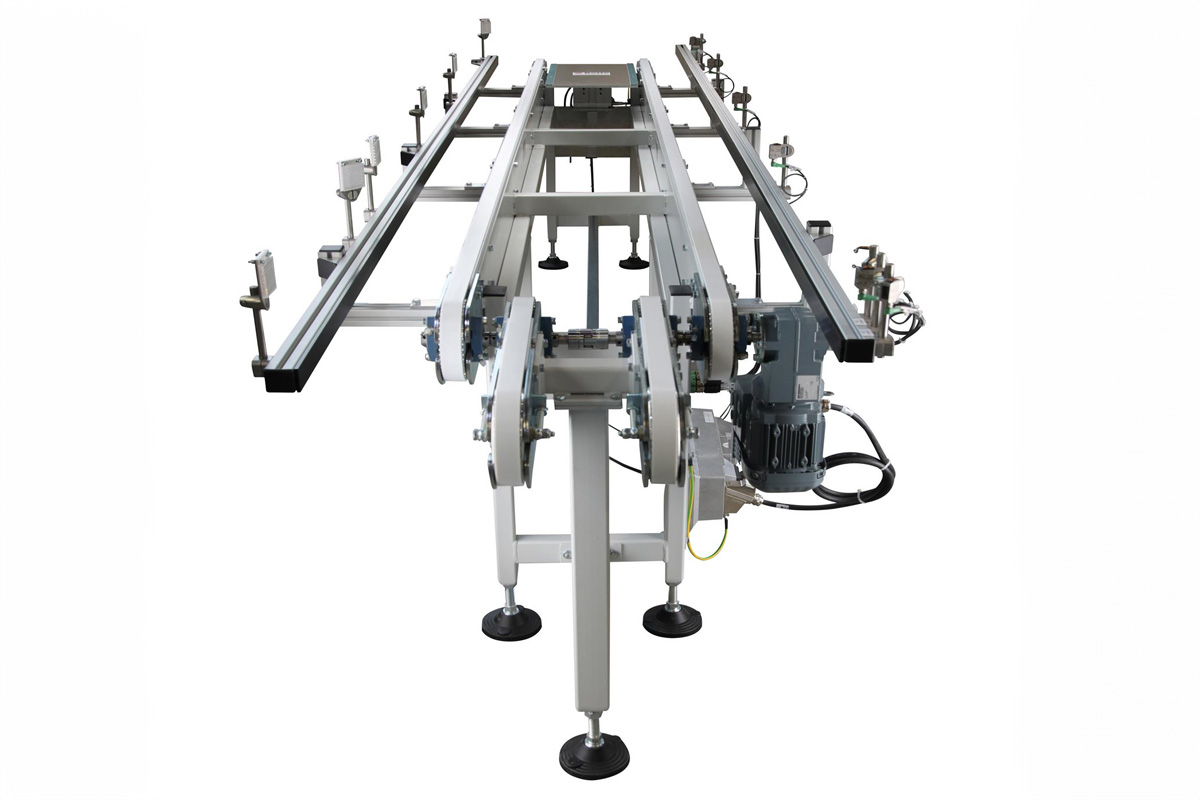

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

For the industrial processing of sealing fleece, filters, and technical fiber materials, Rotte offers high-precision ...

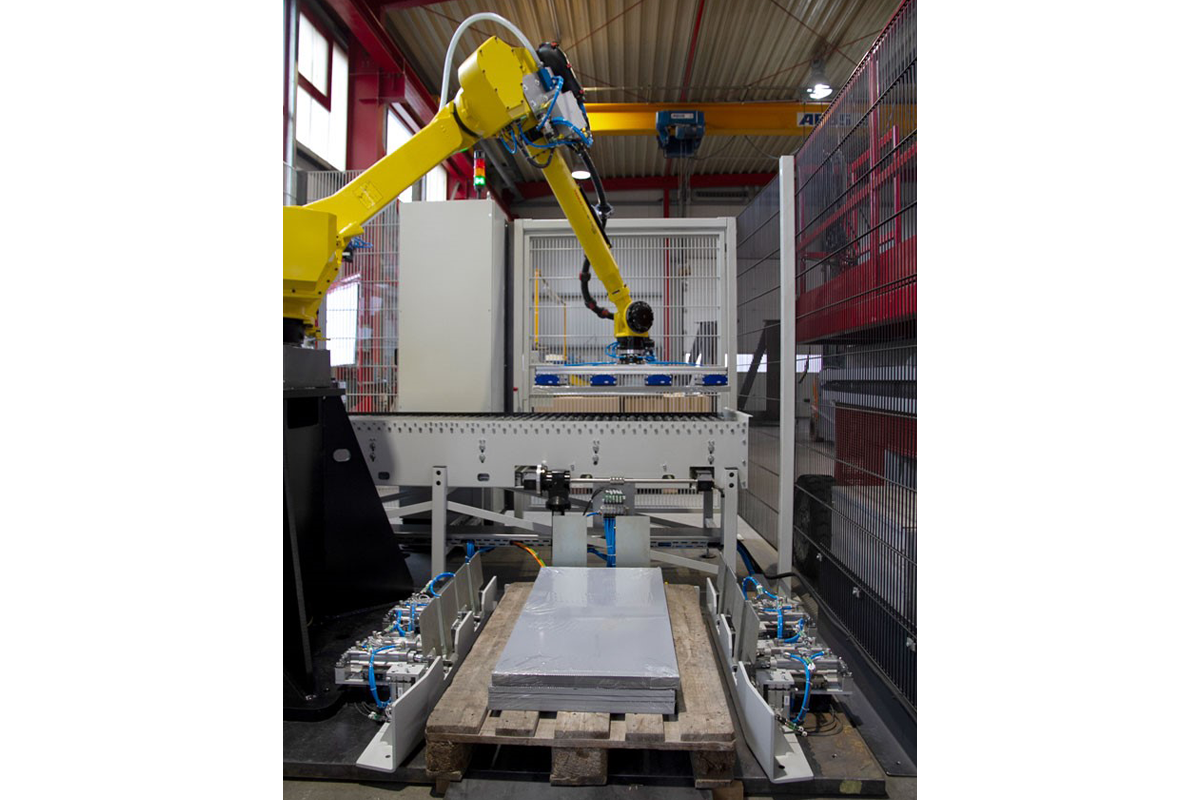

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

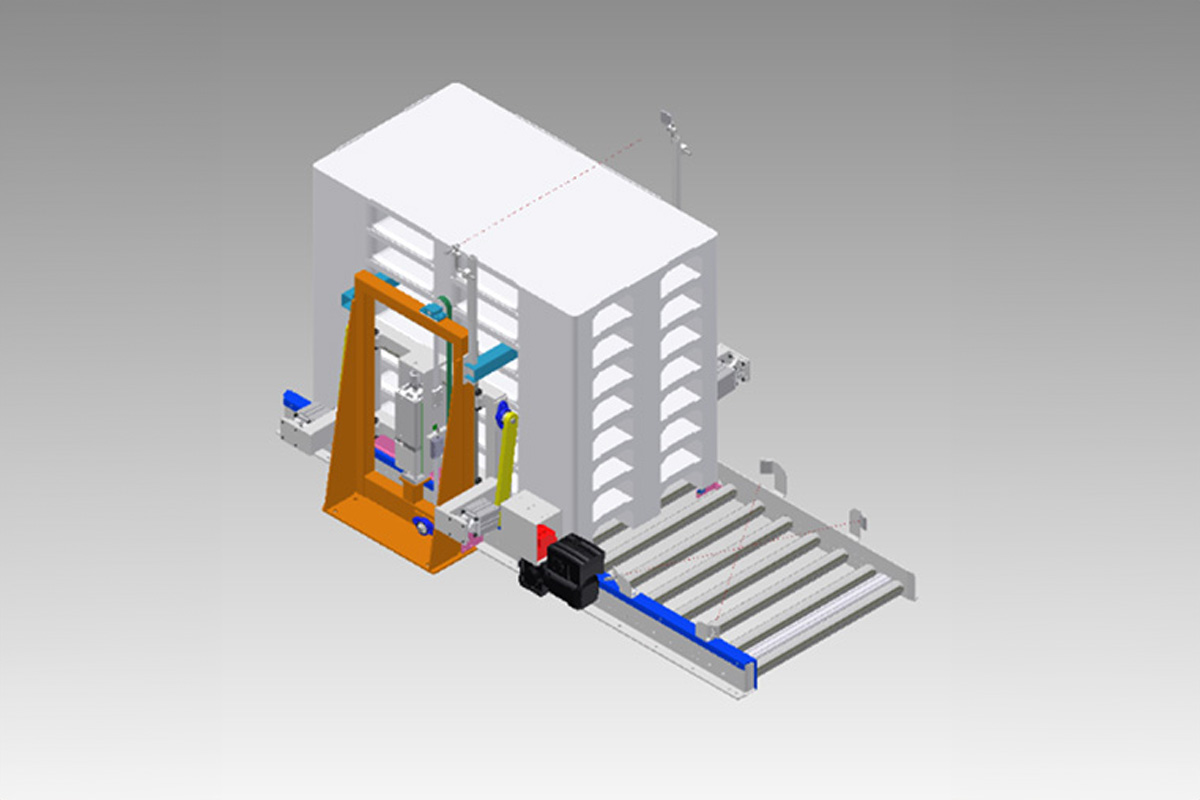

Automated Storage Systems for Multi-Daylight Presses

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...